Hello, welcome to visit anhui Maanshan Zhicheng Machine &Electric Co.,Ltd!

SetHome | AddFavorite | Contact us

Maanshan Zhicheng Machine & Electric Co.,Ltd.

Contact: jian-hua Yang

Tel:13705554456

Address: Maanshan horry huashan district town village in yellow

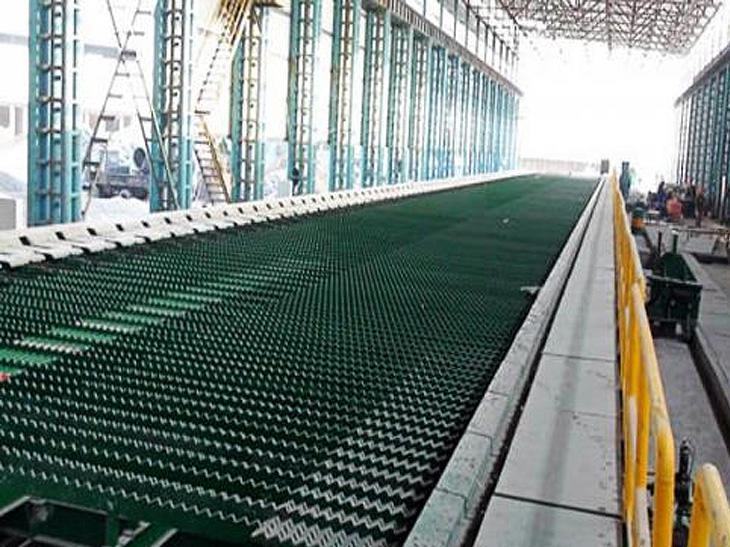

Cold Bed Production Line

Cold Bed Production Line

(1) Product introduction

Our company's cold bed has step-by-step, chain and other products. It is divided into five parts: upper steel device, input roller, cold bed body alignment roller, lower steel device and output roller. Its input roller is driven by frequency conversion motor, and the cooling bed body is driven by double envelope worm gear reducer. It has the advantages of strong driving ability, high efficiency, strong adjustability and long service life. It can make the optimal process design according to the user's requirements.

(2) Major achievements

Our company has successively designed and manufactured more than 20 sets of cold bed production lines for domestic and foreign iron and steel enterprises such as Ma Gang, Xilin Iron and Steel Company, Baosteel Nantong Iron and Steel Company, Qingdao Iron and Steel Company, Amman, Mozambique and so on.

(3) Technical parameters

1. Cooling area: 6m-15m*40m-140 M

2. Linear speed of input roller: 10-20m/s

3. Cooling specifications: 10-60 round and threaded steel

4. 20mm-150mm flat steel, etc.

Bar and small-sized Cold-bed production line products are electric, hydraulic and other two types of transmission;

Medium plate and large-scale cold bed products have disc conveying and chain conveying forms.

It can also be designed according to customer's requirements and actual process on site.

Cold bed is one of the indispensable auxiliary equipment in medium and small bar workshop. Its function is to cut the rod of double length by flying shear after rolling, transport and unload it to the rack of cold bed for cooling, so that its temperature can be lowered from 900 to 100-300 degrees, then collect and send it to the output roll by the cold bed blanking device in groups, and then send it to the cold shear by the output roll table to be cut into fixed-length finished products. The design quality and installation accuracy of the cold bed directly determine the final quality of the product.

In recent years, in order to meet the requirements of various rolling systems, various product specifications, high quality products and high output, our institute has conscientiously digested and absorbed advanced technology at home and abroad, designed a set of high-speed, multi-variety and high-quality small section steel and bar cold bed equipment with the same international advanced level. The annual output of bar can reach 900,000 tons, which has reached the advanced level of similar equipment abroad.

Copyright ©Maanshan Zhicheng Electromechanical Co., Ltd Address :Horry town huang village in Anhui province Maanshan huashan area

TEL:0555-3151761 Phone :13705554456 The url :www.ahzcjd.com/

Email

:zcjdgs@163.com For the record,

:皖ICP备19005449号-1 Technical support

:Operation network

Mobile

Mobile Applet

Applet