Hello, welcome to visit anhui Maanshan Zhicheng Machine &Electric Co.,Ltd!

SetHome | AddFavorite | Contact us

Maanshan Zhicheng Machine & Electric Co.,Ltd.

Contact: jian-hua Yang

Tel:13705554456

Address: Maanshan horry huashan district town village in yellow

Fully automatic hydraulic tipping of 380 tons ladle

Fully automatic hydraulic tipping of 380 tons ladle

Application and Principle of Fully Automatic Hydraulic Tipping Device

Hydraulic tipping device is suitable for ladle repairing, ladle tipping and middle tipping in ironmaking plant's cast iron workshop or similar factory, steelmaking workshop.

Our company is a professional design and manufacture of fully automatic hydraulic tipping device enterprises, at home and abroad have many successful achievements.

Characteristics of Fully Automatic Hydraulic Tipping Device

A. Hydraulic overturning device occupies small area and low space, so the arrangement of equipment in cast iron room is more compact and reasonable after using hydraulic overturning device.

B. Compared with the overturning of metallurgical cranes, the investment of hydraulic overturning can be saved by more than 50%.

C. Compared with electric hoist and metallurgical crane, the hydraulic overturning device is easy to operate, and the ladle overturning process with hydraulic overturning device is smooth and safe.

D. Hydraulic tipping device has the advantages of low operating cost, low equipment loss and easy maintenance.

Advantages of Automatic Hydraulic Tipping Device

A. Reliable control, stable operation, less splash of molten iron and high yield of molten iron;

B. Good man-machine interface, with manual, automatic and side-by-side operation modes; various modes can be switched quickly;

C. In the manual mode, the operation of push-pull can control the casting flow at will.

D. Fully automatic mode, under the condition of setting time, the digital-analog control is to realize the equal flow casting of hot metal.

E. Safe and reliable equipment, long service life; all pipelines built-in concealed design, perfect spatter prevention, burning and insulation measures;

F. Setting up multiple mechanical, hydraulic and electrical safety measures and standby conditions to deal with all kinds of unexpected and dangerous working conditions easily;

G. Reasonable integral structure and special boot-like base structure design make the occupied space and area less, the civil load less, the civil construction workload is very small, the installation and debugging is extremely convenient, and the equipment works stably.

Equipment composition

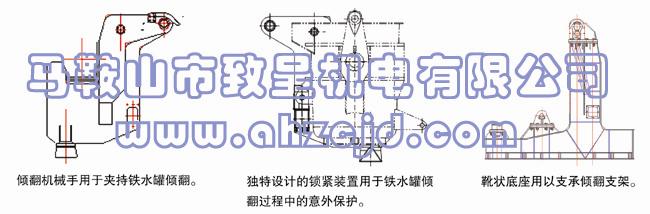

Hydraulic tilting device is mainly composed of mechanical body system (tilting manipulator, tilting hydraulic cylinder, locking device, boot base, angle measuring device), hydraulic station and electrical control system.

Hydraulic intermediate pipeline, locking cylinder pipeline and water-cooled pipeline are all laid inside the boot base, and various heat insulation and radiation protection facilities are laid on the boot base to ensure safe operation.

Hydraulic system and hydraulic station

The overall layout of the hydraulic station is convenient for transportation, installation and maintenance.

The system adopts an independent cycle-cooling-filtering device, which is beneficial to the cleanliness control and working temperature control of the system. The service life of hydraulic components is prolonged and the failure rate is reduced.

Electric control system

Electrical equipment includes: control cabinet, operation table, field operation box, field terminal box, hydraulic station operation box.

The turning speed of the tipping bracket can be set on the operating table, and the status of the hydraulic station and the tipping equipment can be known in real time. The chain speed of the cast iron machine, the liquid level of the cooling pool and the opening state of the cooling water can be displayed.

On-site equipment operation box is mainly used for on-site debugging or maintenance; on-site equipment operation box is equipped with local/remote selection switch, starting, rising, falling and stopping operation buttons and corresponding indicator lights.

Hydraulic station operating box is mainly used to control the operation of hydraulic station when operators debug or repair the hydraulic station on site.

Three operation modes, automatic mode, manual mode and machine-side mode, can be realized by operating table and machine-side operating box.

Copyright ©Maanshan Zhicheng Electromechanical Co., Ltd Address :Horry town huang village in Anhui province Maanshan huashan area

TEL:0555-3151761 Phone :13705554456 The url :www.ahzcjd.com/

Email

:zcjdgs@163.com For the record,

:皖ICP备19005449号-1 Technical support

:Operation network

Mobile

Mobile Applet

Applet